Due to its high resistance to abrasion, fabric made of polyamide (PA) is predominantly processed for motorcycle clothing. Since most of these fibres have a smooth surface, the seam pull-out strength (slide resistance) is very low. In order to prevent the pulling out of the seam, most of these fabrics are coated (often with polyurethane) or laminated (punctiform attachment of a second layer of very thin fabric). Depending on the type and quality of this second layer, the water vapour permeability (breathability) of the fabric will be negatively influenced to greater or lesser degree. The best breathability is offered by the laminated material made of CORDURA® 500, which we use for GORE-TEX® articles. The fine pores between the threads of the fabric are retained here and ensure maximum breathability. This is bettered only by CORDURA® AFT (Air Flow Technology). Almost exclusively materials made of CORDURA® are used for the textile parts of our collection.

CORDURA® materials are an important component of sophisticated motorcycle clothing. Extreme strength and durability enable the design of high-performance clothing that is much lighter than the classic leather clothing. Motorcycle clothing made of CORDURA® materials is comfortable and strong and offers the wearer protection and comfort.

Properties:

Motorcycle clothing with CORDURA® offers

- High resistance to tearing and abrasion

- Ratio of stability to weight without exception

- Wide variety of design possibilities

COVEC® fabrics were developed so that they meet and even exceed the high requirements for the end product in its demanding application, be it for clothing, shoes, backpacks, tents or sails. Through the unique combination of different fibres and fabric constructions, COVEC® fabrics reach a peerlessly high level of resistance to abrasion, tearing, cutting and puncturing, depending on the specific end use.

The TFL COOL SYSTEM® is based on practical physics. Dark colours absorb solar radiation and thus heat up much more than light colours, which reflect up to 95% of the light energy. In the infrared radiation range, the light energy absorbed by the dark materials is transformed into heat. As a result, the material (leather) heats up and gives off this heat again to its surroundings (body). Materials equipped with the TFL COOL SYSTEM® do not absorb any solar radiation in the infrared range – in fact it is reflected. The consequence is that dark materials heat up much less thanks to TFL COOL.

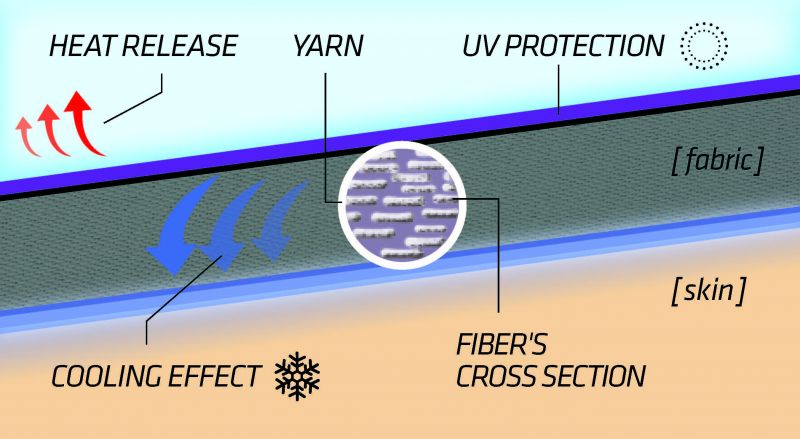

Like a fresh breeze, the revolutionary NILLIT BREEZE yarn gives the wearer a refreshing and comfortable feeling when temperatures rise.

The cooling effect of NILLIT BREEZE can be attributed to 3 factors:

- Due to the flat cross-section and the resulting large surface area, body heat is quickly transported onwards.

- A unique polymer containing inorganic microparticles enlarges the surface area and forms small channels in order to promote cooling.

- Special textile processes enables the manufacture of a yarn with small dimensions, from which clothing with maximum breathability and ventilation is produced.

- helps to maintain a pleasant body temperature during/after physical exertion and in hot weather

- optimally supports physical performance

- ensures efficient ventilation

Materials made from Polartec® Wind Pro® are extremely breathable and hold back four times as much wind as conventional fleece. It is a new "super fleece" that covers an unbelievably wide range of weather conditions. It is extremely durable and is suitable both for outer wear and for thermal insulation.

- wind-repellent

- warmth without weight

- water-repellent

- extremely breathable/li>

- easy-care

Material: 100% polyester

Microfleece is a fleecy, soft material roughened on one side. The material provides for a high degree of thermal insulation with a low weight.

- Breathability and the transport of moisture to the outside are ideal.

- fast moisture transport

- quick drying

- breathable

- high basic elasticity

- good thermal insulation

- anti-pilling

- ideal body climate

- light, soft, skin-friendly

schoeller® dynatec is the result of decades of research in the field of protective fabrics. The heart of the fabric is a nylon-based fibre (Dynafil TS-70) that exhibits excellent protective functions.

- tear-resistant

- abrasion-resistant

- durable

- water/dirt/oil-repellent

- high wearing comfort

- easy-care

We use dynatec® almost exclusively with woven-in 3M ScotchliteTM threads in order to increase visibility in the dark or poor weather conditions.

A declaration regarding the CE-tested protectors that we use can be found here.